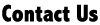

A company that is seeking to build an underground liquid carbon dioxide pipeline held an event in Jefferson on Thursday morning.

Summit Carbon Solutions staff were at the Greene County ISU Extension Office hosting a safety open house where impacted landowners and the general public could attend to learn more about the safety measures and regulations that are a part of their proposed project. Summit is seeking to construct an underground pipeline in five Midwest states that would capture carbon emissions from ethanol plants and compress it into a liquid that would be transported via a pipeline to an underground storage facility in North Dakota that would be 1 to 1.5 miles below ground level.

Senior Pipeline Project Manager Grant Terry said the construction phases are constantly being inspected and reviewed for quality assurance. He explained the initial step is a survey is done of the easement on the property, followed by different crews that are clearing, preparing, welding and installing the pipe into the ground, to the final tests and the restoration of returning the area to pre-construction conditions can take up to 120 non-consecutive work days.

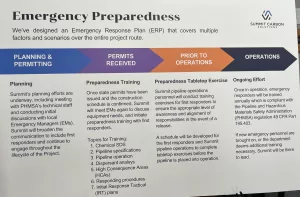

Terry noted that this project is regulated by several agencies, with the primary being the Pipeline and Hazardous Materials Safety Administration (PHMSA) with the US Department of Transportation. He mentioned that PHMSA has specific regulations in place under 49 CFR 195 pertaining to hazardous liquid pipelines including carbon dioxide, which also conducts audits with subject matter experts at each step of the pipeline process, including yearly operational audits. Terry pointed out there are additional permits and regulations with the US Army Corps of Engineers, US Fish and Wildlife Services, and Natural Resources Conservation Services, among others.

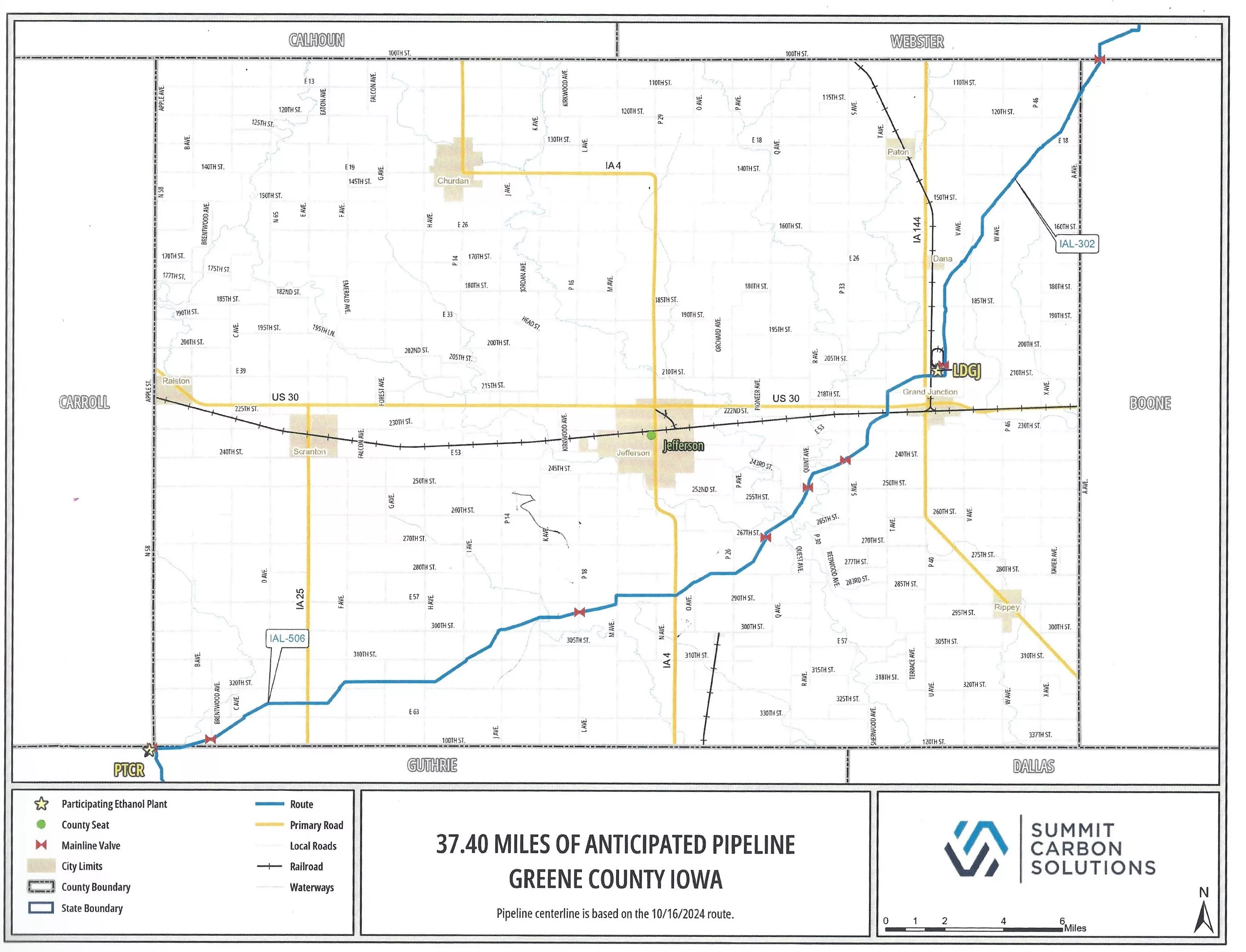

Terry said across the industry that are safety designs for both preventive and mitigation barriers based on statistics that have action plans in place. He described the most common occurrence for a potential leak of a pipeline is known as a “3rd party strike” where someone is going to dig into the ground and they hit the pipeline because the pipeline was not properly marked above ground and that individual did not call 811 to locate all underground utilities. Other preventative barriers include natural disasters, internal and external corrosion factors, and construction defects.

Terry said across the industry that are safety designs for both preventive and mitigation barriers based on statistics that have action plans in place. He described the most common occurrence for a potential leak of a pipeline is known as a “3rd party strike” where someone is going to dig into the ground and they hit the pipeline because the pipeline was not properly marked above ground and that individual did not call 811 to locate all underground utilities. Other preventative barriers include natural disasters, internal and external corrosion factors, and construction defects.

Senior Director with HSSE Dave Daum mentioned some of the mitigation barriers include public awareness and warning systems to first responders getting training on the tactical plans in the different areas of the pipeline, along with providing carbon dioxide detectors and an initial $50,000 grant for local first responders to purchase equipment needed to respond to a leak if it happens. Summit staff added that only a handful of people attended part of the come and go, two hour open house.